Table of Contents 1. Testing of robot cables - Testing of robotic cables - An introduction to DYDEN’s testing machines 2. Calculation of robot cable service life - An introduction to service life simulation software

1. Testing of robot cables

Testing of robotic cables

Robot cables must be able to bend and twist to cope with the intense movement of a robot.

When selecting a robot cable, its bending and twisting properties need to be assessed.

DYDEN performs durability tests upon customer request.

An introduction to DYDEN’s testing machines

We have 3 types of testing machines.

- ±90° bending test

Evaluates the durability of robot cables by bending them through ±90°.

Information on testing machines

Number of machines we have : 26

Bending radius (R) accommodated : 5 mm to 120 mm

Information required to conduct the test

・ R

- Torsion test

Evaluates the durability of a robot cable by twisting it to the desired angle.

Information on testing machines

Number of machines we have : 29

Angles accommodated : ±45° to 360°

Fixed lengths accommodated : up to 1,000 mmInformation required to conduct the test

・ Angle of torsion

・ Distance between anchoring points

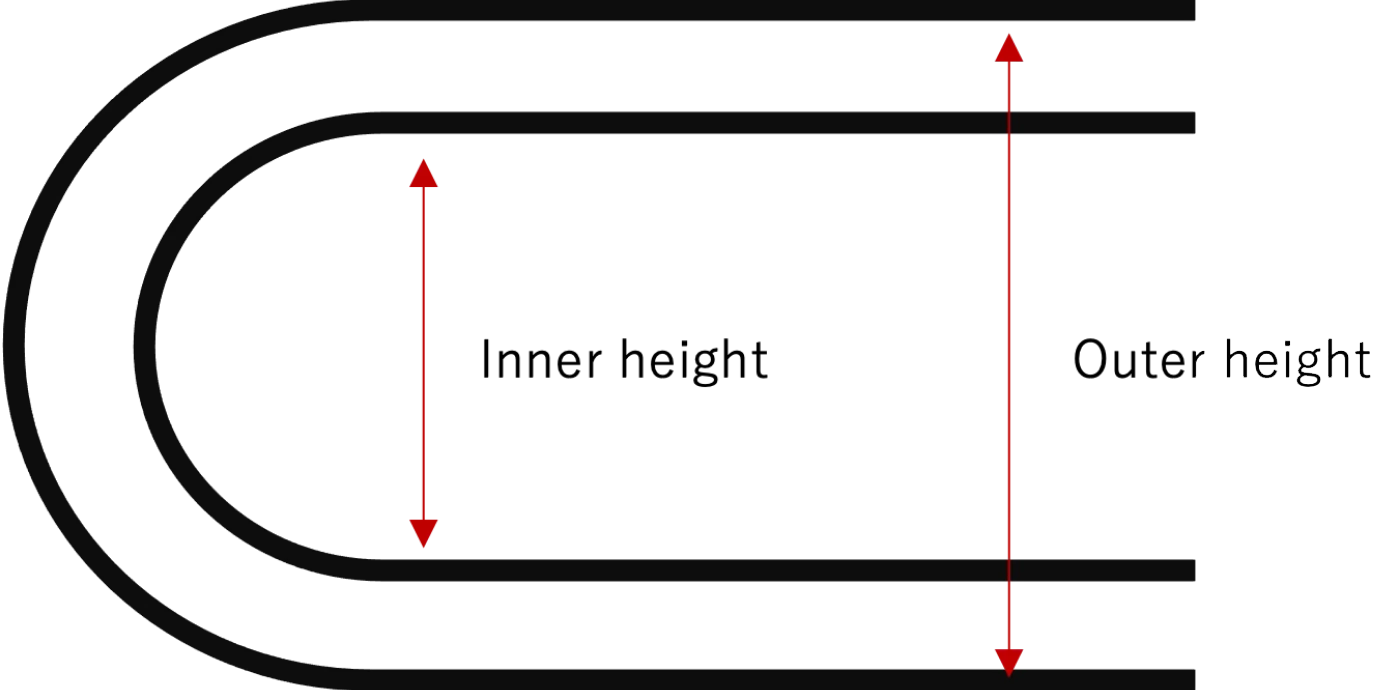

- U bending test

Evaluates a robot cable’s durability by routing it to the cable guide and operating the cable.

Information on testing machines

Number of machines we have : 22

R accommodated : up to 150 mm

Stroke accommodated : 180 mm to 15,000 mmInformation required to conduct the test

・ Inner and outer height of the cable guide (or the model of cable guide)

・ Stroke

・ Maximum acceleration

2. Calculation of robot cable service life

An introduction to service life simulation software

Evaluating the durability of a robot cable with a testing machine may take a considerable amount of time depending on the test conditions.

Based on the test data we have accumulated over many years and basic data on each material, we have developed software to simulate a cable’s service life.

Using this software, we can calculate the service life of a robot cable in a short amount of time with a high degree of accuracy.

(The simulation results are not guaranteed values but reference values)

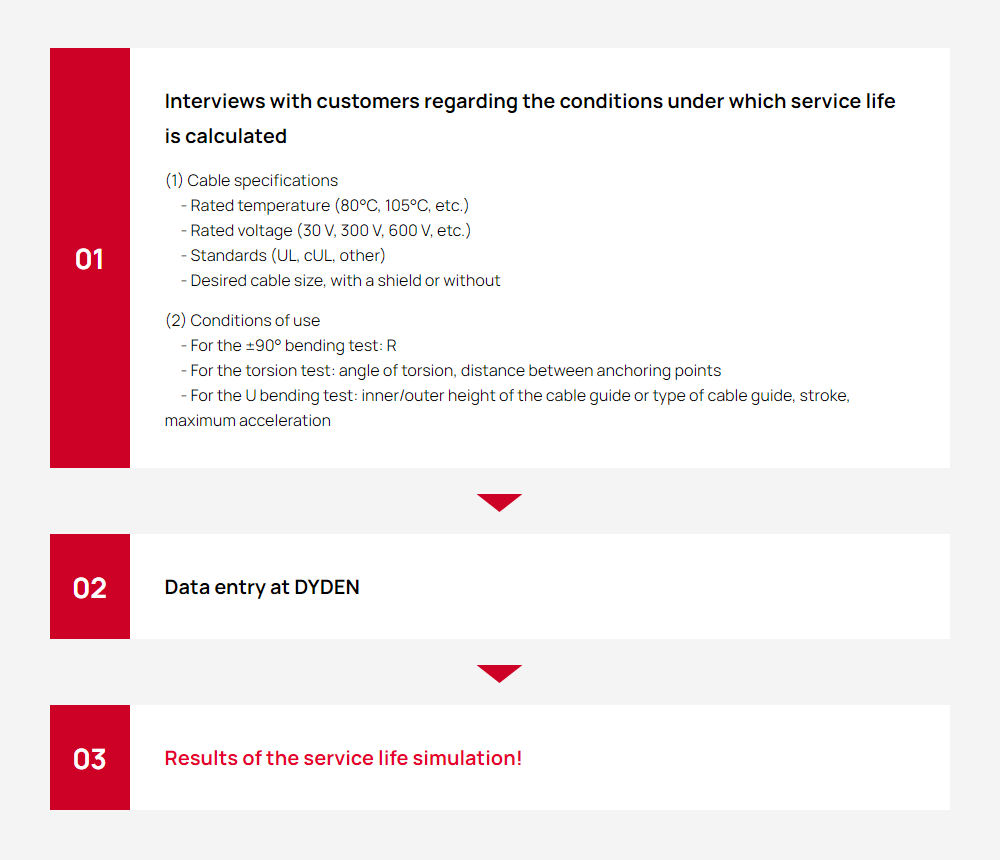

Steps in simulation

If you would like us to conduct a durability test of a robot cable or calculate its service life using our software, please contact us via the contact page below.