Table of Contents 1. What is the recommended bend radius? - What is the recommended bend radius? 2. Recommended bend radius for each series - Recommended bend radius for the RMFEV and RMCV series - Recommended bend radius for RMDH and RMDV series 3. When using robot cables under severe operating conditions - Suggesting the RM205 series of highly durable robot cables with a small bend radius

1. What is the recommended bend radius?

What is the recommended bend radius?

Although the composition of our robot cables is designed to be resistant to bending and twisting, cracks in the insulation or sheath or buckling of the wire core may occur if the cables are used under harsh conditions.

From the viewpoint of preventing disconnections, we have specified a recommended bend radius (recommended R) for each series of robot cables.

In a durability test of robot cables conducted with the recommended bend radius, we have confirmed results from 20 million or more attempts.

2. Recommended bend radius for each series

Recommended bend radius for the RMFEV and RMCV series

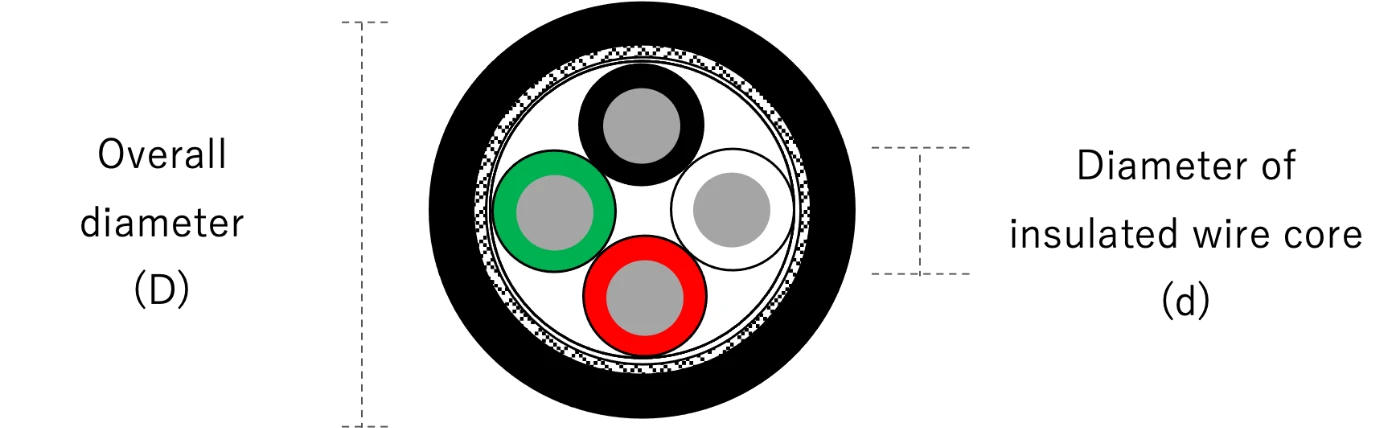

At least 33 times the diameter of the insulated wire core and at least 6 times the overall diameter of the robot cable

Recommended bend radius for RMDH and RMDV serie

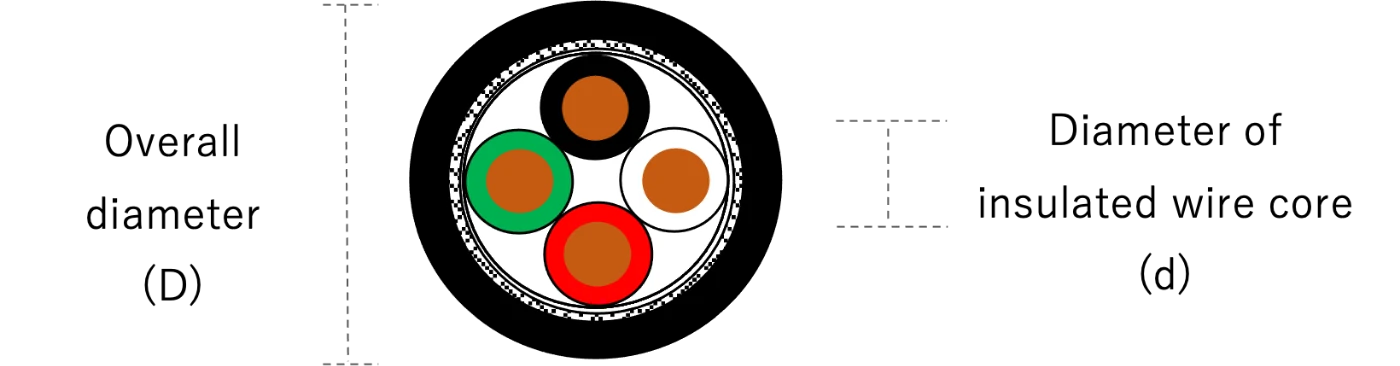

At least 33 times the diameter of the insulated wire core and at least 6 times the overall diameter of the robot cable

*If R is 40 mm or less, the recommended R is 40 mm

You can check the recommended R for each size of each series.

For a list of each robot cable series, click here.

3. When using a robot cable under harsh operating conditions

Suggesting the RM205 series of highly durable robot cables with a small bend radius

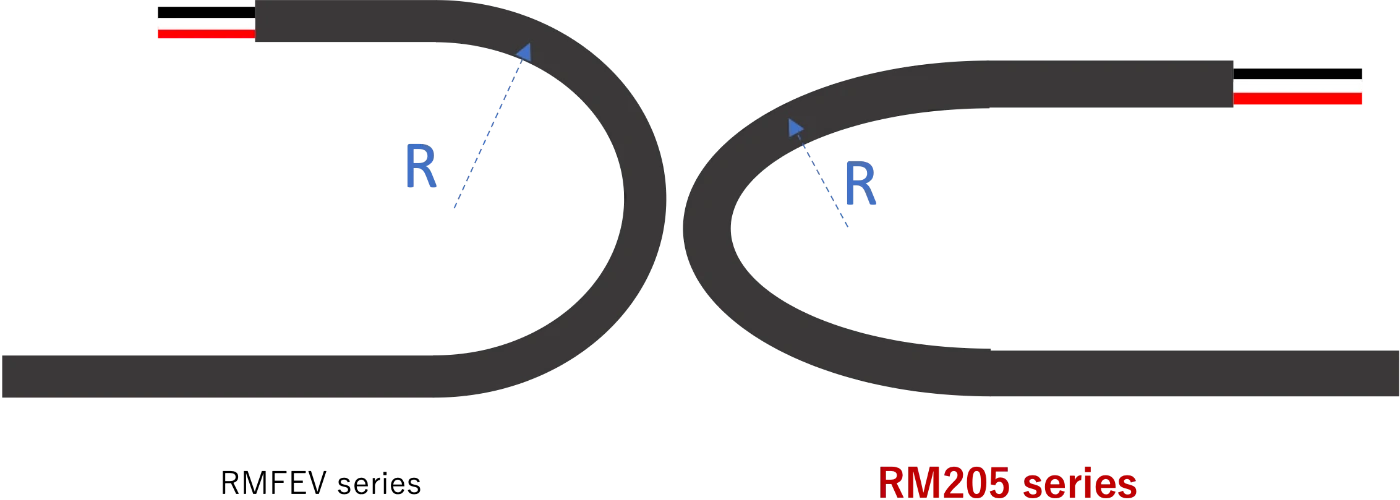

For use under severe conditions, we suggest our RM205 series of highly durable robot cables with a small bend radius.

The RM205 series is a series of durable robot cables with a small bend radius. The recommended bend radius is at least 20 times the diameter of the insulated wire core and at least 5 times the overall diameter of the robot cable.

This series has a bend radius that is at least 20 times the diameter of the insulated wire core and at least 5 times the overall diameter of the robot cable.

The results of a test conducted under harsh conditions are as follows.

| Test | Conditions | Cable | Test results |

|---|---|---|---|

| ±90° bending test | R=15 mm | RMFEV-SB(2517) AWG30/2P | 50 million disconnections |

| ±90° bending test | R=15 mm | RM205-SBX(c21885) AWG30/2P | 100 million or more disconnections |

| Torsion test | L=100 mm ±180°C | RMFEV-SB(2517) AWG24/4P | 30 million disconnections |

| Torsion test | L=100 mm ±180°C | RM205-SBX(c21885) AWG24/4P | 160 million or more disconnections |

As mentioned above, the RM205 series are the robot cables best suited to use under harsh conditions.

For more details, please refer to the product page for the RM205 series.

If you have any other requests, please feel free to contact us.