Table of Contents 1.Special conductors - Copper alloy conductors 2.Special shields - Flexible Shields 3.Special jacket -Low Friction jacket -Low-outgassing PVC jacket

1. Special conductors

We comprehensively assess the bending resistance of and ease of connector attachment to conductors. As a result, we also use soft copper wire (tin-plated soft copper wire) in our robot cables, but we also offer special conductors depending on the operating environment.

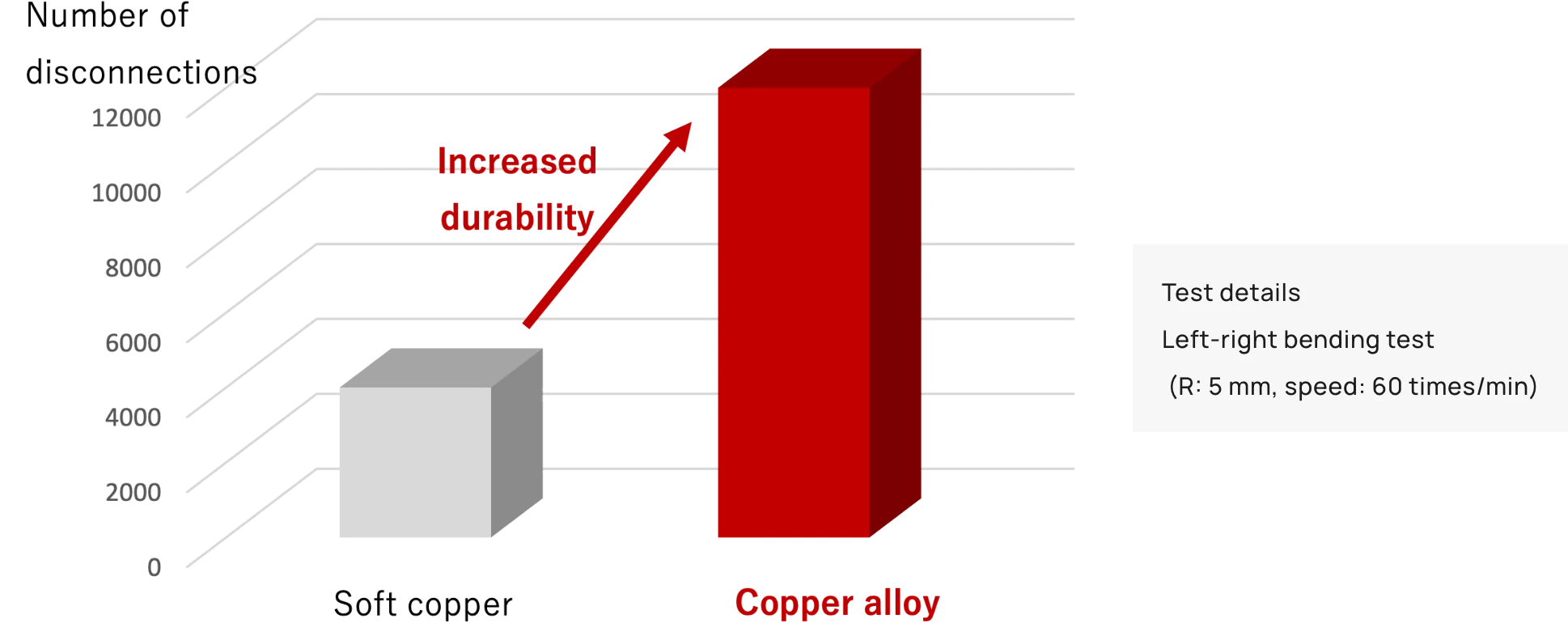

Copper alloy conductors

For use under harsh operating conditions, we suggest a copper alloy conductor as a special conductor.

Robot cables with copper alloy conductors have greatly increased bending resistance compared to those with soft copper conductors.

The results of tests comparing our copper alloy conductors to soft copper conductors are as follows.

2. Special shields

We comprehensively assess the bending resistance of and shielding provided by shields. As a result, we use braided shields (with -SB in the model number) in our robot cables, but we also offer several types of special shields depending on the operating environment.

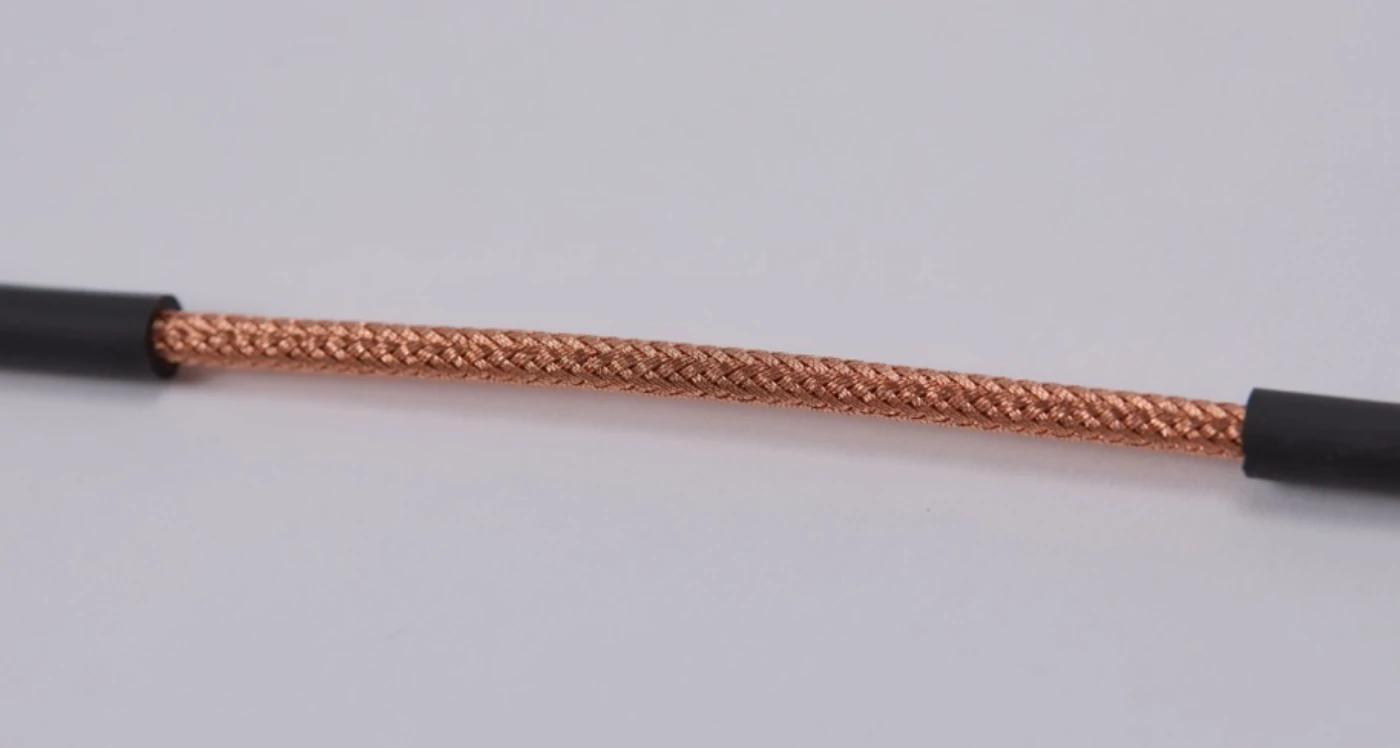

Flexible Shields

For use under harsh operating conditions, we suggest a bend-resistant shield as a special shield.

It has excellent bending and twisting resistance while providing shielding equivalent to that of a braided shield.

Robot cables with flexible shields have “-SLABX” in the model number.

E.g.) RMFEV-SLABX

We also offer lateral winding shields and metal tape shields, which have a smaller outer diameter than braided shields.

3.Special jacket

We use flame-retardant and oil-resistant PVC for the jacket in our robot cables because of its flame-retardant and oil-resistant properties. We also offer several types of special jacket depending on the operating environment.

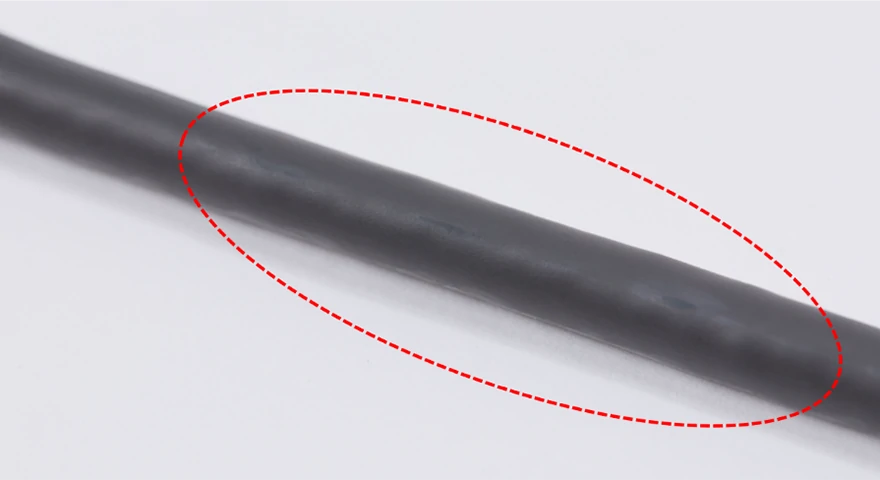

Low Friction jacket

If a robot cable is used inside a robot or cable guide and its jacket is worn, we suggest a low Friction jacket.

Low Friction jacket have less wear resistance than flame-retardant and oil-resistant PVC jacket, allowing reduced jacket wear.

The results of a durability test conducted under the same conditions are shown in the following pictures.

Jacket wear is evident on a robot cable with a flame-retardant and oil-resistant PVC jacket, while there is almost no wear on the robot cable with a low Friction jacket.

Robot cables with a low Friction jacket have an “S” in the model number

E.g.) RMFES-SB

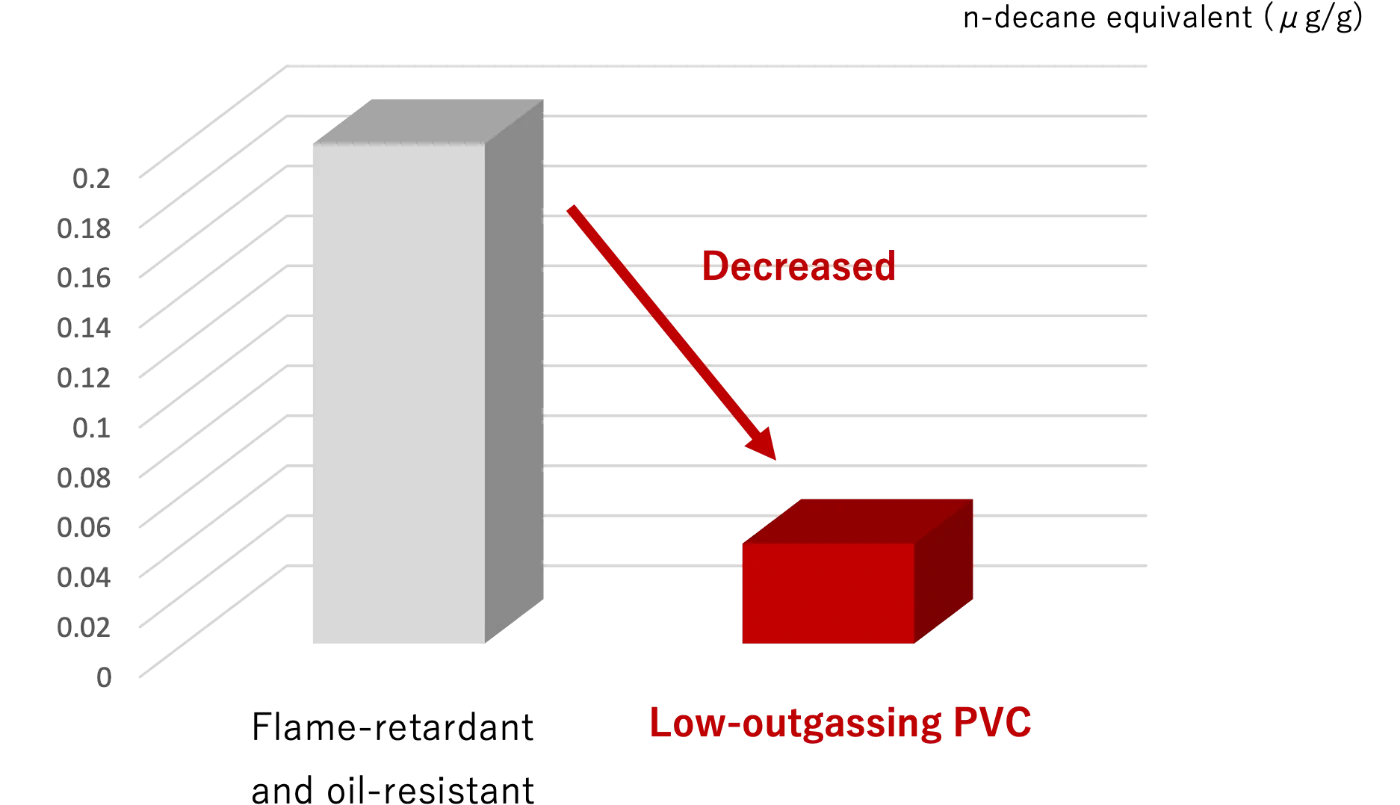

Low-outgassing PVC jacket

When using robot cables in places where you want to limit outgassing, we suggest a low-outgassing PVC jacket.

Outgassing can be reduced by using a low-outgassing PVC jacket.

Compared to flame-retardant and oil-resistant PVC jacket, low-outgassing PVC jacket can reduce the amount of outgassing to about 1/3.

Robot cables with a low-outgassing PVC jacket have “-LG” in the model number.

E.g.) RMFEV-LG

In addition to the above, we also offer a cold-resistant jacket that can be used in environments with temperatures down to -40°C.

If you have any requests for robot cables with special conductors, special shields, or special jacket, please contact us via the contact page below.