Table of Contents 1.What are robot cables? -What are robot cables? -Components of a robot cable 2.DYDEN’s robot cables -Features of DYDEN’s robot cables -DYDEN’s share of the domestic market for robot cables 3.Selection of robot cables

1. What are robot cables?

What are robot cables?

Robot cables are cables used in industrial robots.

(these cables are also called cables for moving parts or cables for FA)

At first glance, these cables seem just like ordinary cables, but robot cables have bending and twisting properties to cope with the intense movements of robots, and this is a major difference between them and ordinary cables.

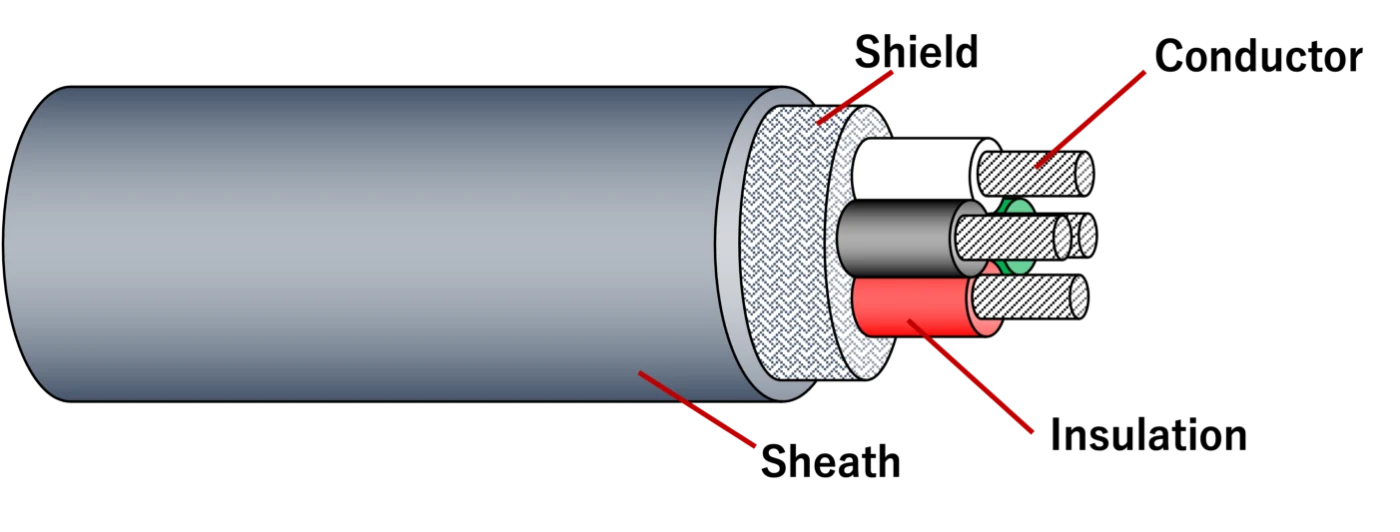

Components of a robot cable

The general components of a robot cable are as follows.

| Role | |

|---|---|

| Conductor | Transmits electricity for power, signals, etc. |

| Insulation | Interrupts the conduction of electricity. |

| Shield | Prevents noise. |

| Jacket | Prevents damage and provides oil resistance |

Cable compositions are devised and optimal materials are selected for the components above to improve the bending and twisting properties of robot cables.

We describe how to select the conductor composition and insulation materials for DYDEN’s robot cables.

For more information, click here.

2. DYDEN’s robot cables

Features of DYDEN’s robot cables

There are several manufacturers of robot cables just in Japan, including DYDEN.

So “what are the features of DYDEN’s robot cables?”

DYDEN’s robot cables have three main features.

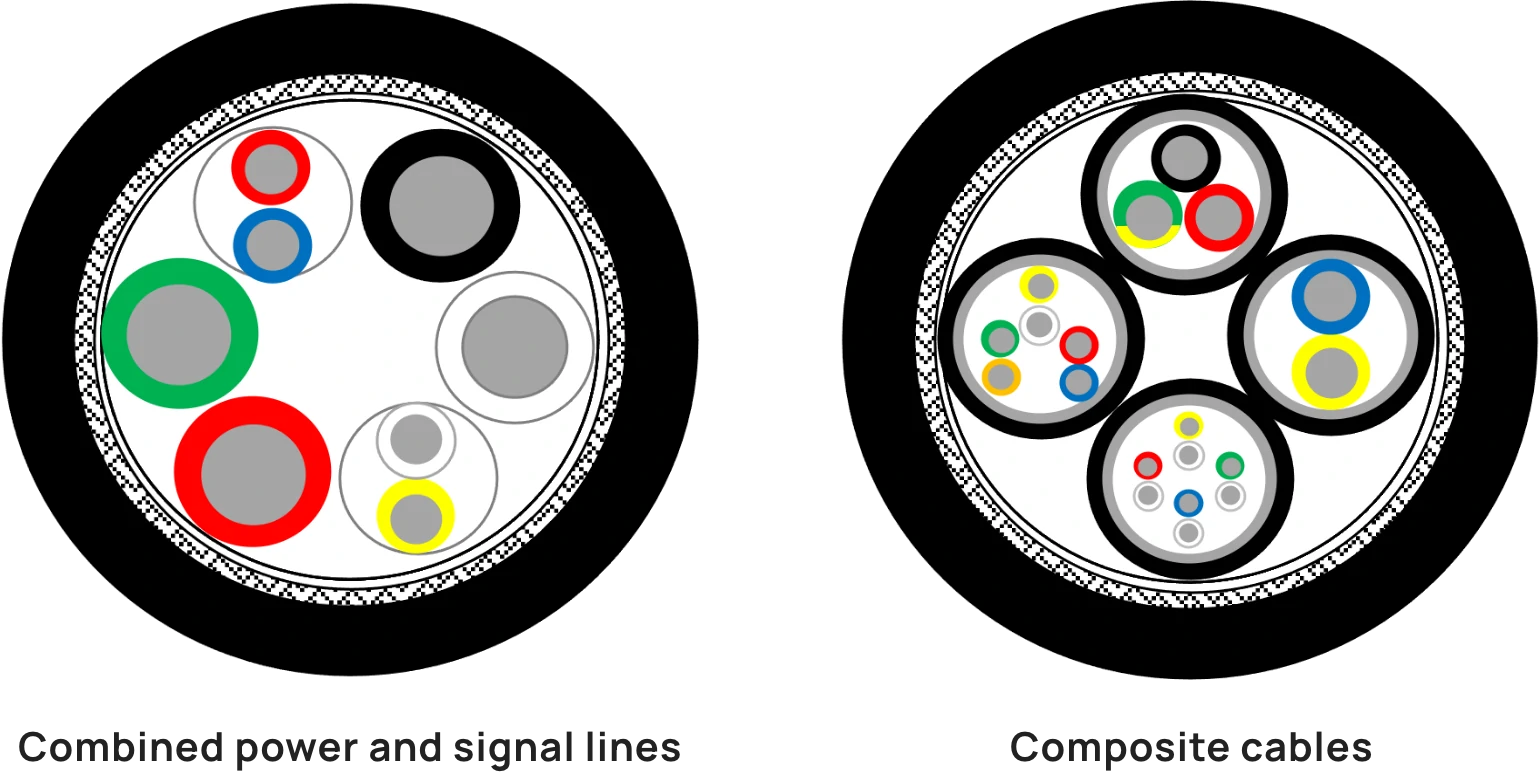

- We suggest custom-designed robot cables

In addition to the lineup of products listed on our website, we also offer custom designs to meet your needs.

For example, we can respond to various requests such as combining power and signal cables or composite cables.

Composite cables in particular are ideal for places with limited space for wiring, such as inside a robot, and these cables are favored by many of our customers.

We custom-design robot cables free of charge. Please feel free to contact us

- A track record of over 40 years and data (reliability)

DYDEN has been dealing in robot cables for over 40 years since we started manufacturing robot cables in 1983.

The know-how and technical expertise we have accumulated through repeated severe bending and torsion tests has resulted in a long service life and a high level of durability for DYDEN’s robot cables.

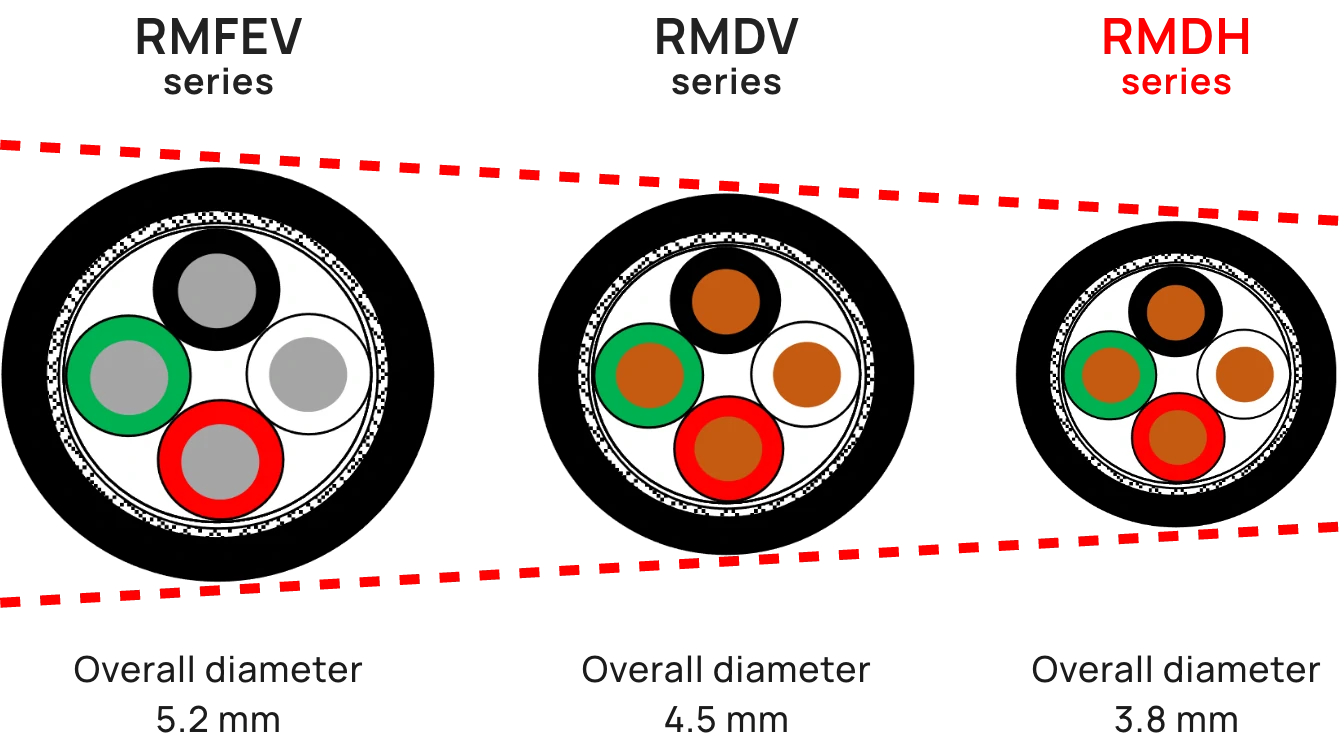

- In-house development of materials for robot cables

We develop the optimum cable material depending on how our customers will use a robot cable.

As an example, the insulation material used in the RMDH series of ultra-thin, highly durable robot cables is a special elastomer jacket with a smaller diameter we developed to reduce the size of a robot and for wiring to take up less space.

We offer diameters that are among the smallest in the industry!

For more information about the RMDH series of ultra-thin, highly durable robot cable, click here.

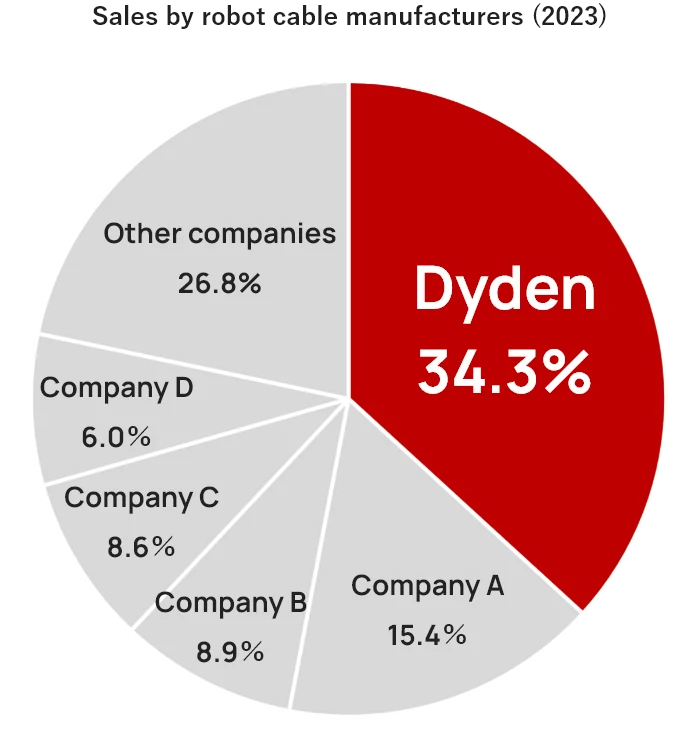

DYDEN’s share of the domestic market for robot cables

Because of these 3 features, DYDEN’s robot cables are well-regarded by various users, such as major robot manufacturers.

In the highly competitive robot cable industry, DYDEN’s robot cables have maintained the No. 1 share in the domestic market for over 20 years.

(*Refer to Fuji Keizai’s No. 1 The Robot-related Market Worldwide: Current Status and Prospects for the Future, Robots for FA)

(*Refer to Fuji Keizai’s No. 1 The Robot-related Market Worldwide: Current Status and Prospects for the Future, Robots for FA)

3. Selection of robot cables

We have a page on selecting robot cables to help you select the optimum robot cable from among the many series that we have.

You can select the optimum robot cable by simply indicating your intended use of the robot cable.

We hope you give it a try.

If you have any requests such as “we want you to suggest the optimum robot cable,” please feel free to contact us.