Main applications

Wiring in industrial equipment such as semiconductor manufacturing equipment and machine tools, ground wires, etc.

*Fixed wiring

Wire specifications and certifications

| Japan | US | Canada | Europe | UK | ||

|---|---|---|---|---|---|---|

| Certification | PSE | UL MTW | UL AWM | CSA AWM | TUV CE marking | TUV UKCA marking |

| Applicable standards Applicable safety standards | Electrical Appliance and Material Safety Act | UL 1063 | UL 758 | C22.2 No. 210 | EN 50525-2-31 | BS EN 50525-2-31 |

| Code | H-KIV | MTW | UL STYLE 1015 | l, A/B Oil Resistant | H07V-K | H07V-K |

| Rated voltage | 600 V | 600 V | 600 V | 600 V | 450/750 V | 450/750 V |

| Rated temperature | 75°C | 90°C | 105°C | 105°C | 70°C | 70°C |

| Flame retardance | JIS C 3005 | VW-1 | VW-1 | FT1 | EN50265-2-1 | EN50265-2-1 |

Configuration table

| Size | Calculated cross- sectional area | Conductor composition | Conductor outer diameter | Insulation thickness | Overall diameter | Maximum overall diameter | Approximate weight |

|---|---|---|---|---|---|---|---|

| AWG | mm2 | no./mm | mm (approx.) | mm | mm (approx.) | mm | kg/km |

| 18 | 0.84 | 33/0.18 | 1.2 | 0.85 | 2.9 | 3.4 | 16 |

| 16 | 1.50 | 59/0.18 | 1.6 | 0.85 | 3.3 | 3.8 | 23 |

| 14 | 2.16 | 85/0.18 | 1.9 | 0.90 | 3.7 | 4.2 | 31 |

| 12 | 3.56 | 7/20/0.18 | 2.7 | 0.90 | 4.5 | 5.0 | 48 |

| 10 | 5.52 | 7/31/0.18 | 3.4 | 1.00 | 5.4 | 5.9 | 75 |

| 8 | 8.91 | 7/50/0.18 | 4.3 | 1.30 | 6.9 | 7.4 | 120 |

| 6 | 14.07 | 7/79/0.18 | 5.4 | 1.70 | 8.8 | 9.3 | 185 |

| 4 | 22.27 | 7/125/0.18 | 6.8 | 1.70 | 10.2 | 11.2 | 275 |

| 2 | 35.45 | 7/199/0.18 | 8.6 | 1.80 | 12.2 | 13.2 | 425 |

| 1 | 44.48 | 19/92/0.18 | 9.8 | 2.30 | 14.4 | 15.4 | 540 |

| 1/0 | 56.57 | 19/117/0.18 | 11.0 | 2.30 | 15.6 | 16.6 | 665 |

| 2/0 | 73.49 | 19/152/0.18 | 12.6 | 2.30 | 17.2 | 18.2 | 850 |

| 3/0 | 91.61 | 12/300/0.18 | 14.7 | 2.30 | 19.3 | 20.3 | 1,050 |

| 4/0 | 116.04 | 19/240/0.18 | 15.8 | 2.30 | 20.4 | 21.9 | 1,290 |

| 250kcmil | 130.61 | 7/232/0.32 | 15.9 | 2.70 | 21.3 | 22.8 | 1,480 |

| 300kcmil | 157.63 | 7/280/0.32 | 18.0 | 2.70 | 23.4 | 24.9 | 1,770 |

| 350kcmil | 181.28 | 7/322/0.18 | 18.7 | 2.70 | 24.1 | 25.6 | 2,000 |

| 400kcmil | 212.80 | 7/378/0.32 | 21.0 | 2.70 | 26.4 | 27.9 | 2,340 |

| 500kcmil | 258.89 | 37/87/0.32 | 23.6 | 2.70 | 29.0 | 30.5 | 2,750 |

| 600kcmil | 312.45 | 37/105/0.32 | 24.7 | 3.10 | 30.9 | 32.4 | 3,320 |

| 650kcmil | 336.26 | 37/113/0.32 | 27.0 | 3.10 | 33.2 | 34.7 | 3,580 |

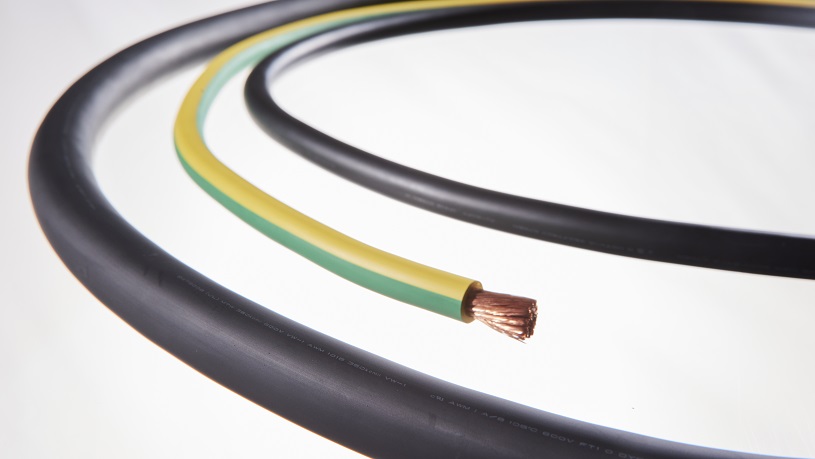

Standard Wire Color: Black

Allowable current as specified in NFPA 79

[Conditions] Number of cores: 3 or fewer, Ambient temperature: 30°C

| Size | Dry 90℃ | WET 60℃ |

|---|---|---|

| AWG18 | 14 | 7 |

| AWG16 | 18 | 10 |

| AWG14 | 25 | 15 |

| AWG12 | 30 | 20 |

| AWG10 | 40 | 30 |

| AWG8 | 55 | 40 |

| AWG6 | 75 | 55 |

| AWG4 | 95 | 70 |

| AWG3 | 110 | 85 |

| AWG2 | 130 | 95 |

| AWG1 | 145 | 110 |

| AWG1/0 | 170 | 125 |

| AWG2/0 | 195 | 145 |

| AWG3/0 | 225 | 165 |

| AWG4/0 | 260 | 195 |

| 250kcmil | 290 | 215 |

| 300kcmil | 320 | 240 |

| 350kcmil | 350 | 260 |

| 400kcmil | 380 | 280 |

| 500kcmil | 430 | 320 |

| 600kcmil | 475 | 355 |

| 700kcmil | 520 | 385 |

| 750kcmil | 535 | 400 |

| 800kcmil | 555 | 410 |

| 900kcmil | 585 | 435 |

| 1000kcmil | 615 | 455 |

*This table shows only values from NFPA 70 and NFPA 79. Adjustment factors may differ depending on the actual operating environment.

For actual selection, refer to NFPA 70 and NFPA 79.