Written by DYDEN Web Team

Robotic cables is cables used for industrial robots, and is also called Robot cables, Continuous flex cables or Flex cables.

Here, we will clearly explain the differences between Robotic cables and standard cables, which at first glance may not be obvious, thier structure, features of DYDEN's robotic cables, and its market share in Japan.

Table of Contents 1.What are Robotic cables - Difference from standard cables - Robotic cables structure Conductor Insulation Shield Jacket 2.About DYDEN's Robotic cables - Three features ①More than 40 years of experience and data (reliability) ②Custom design suggestions! ③In-house material development! - Market share in Japan 3.Summary

What are Robotic cables?

Difference from standard cables

Simply put, Robotic cables are cables used inside an industrial robot or for its equipment.

(they are also called Robot cables, Continuous flex cables or Flex cables.)

At first glance, they look no different from typical standard cables, but there are one big difference.

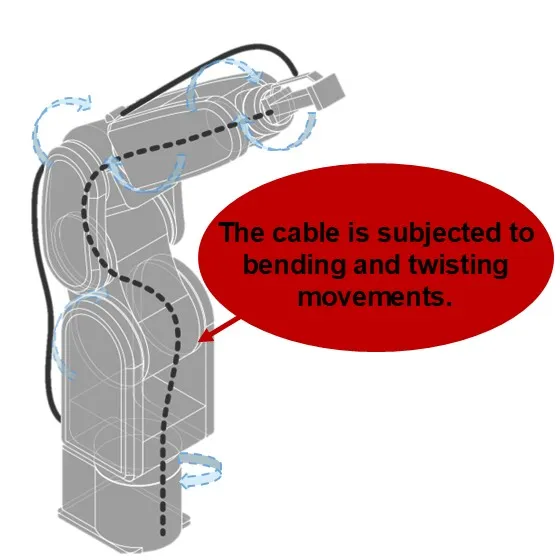

The point is that Robotic cables have the ability to bend and twist.

In the case of 6 axis robot and SCARA robot, each axis moves like a human arm, so the cable wired to the robot are subjected to bending and twisting movements.

Ordinary standard cables cannot withstand this bending and twisting and will break.

However, Robotic cables are designed with flexibility and twisting ability so that they can withstand these harsh movements.

This is a major difference from standard cable.

Robotic cables structure

So what kind of structure does it have?

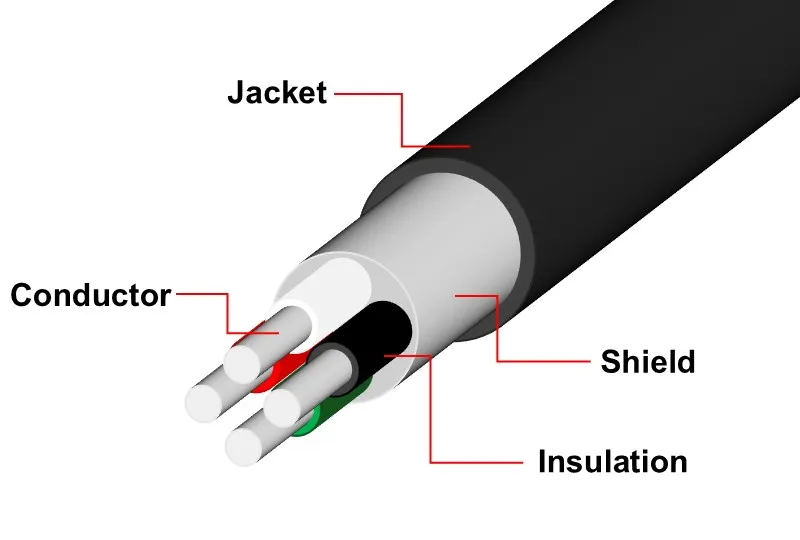

The general structure is as follows:

So then, we will introduce the roles of each department.

| Conductor | Transmitting electricity such as power and signals |

| Insulation | Blocking the conduction of electricity |

| Shield | Preventing noise |

| Jacket | Preventing external damage and providing oil resistance |

Conductor

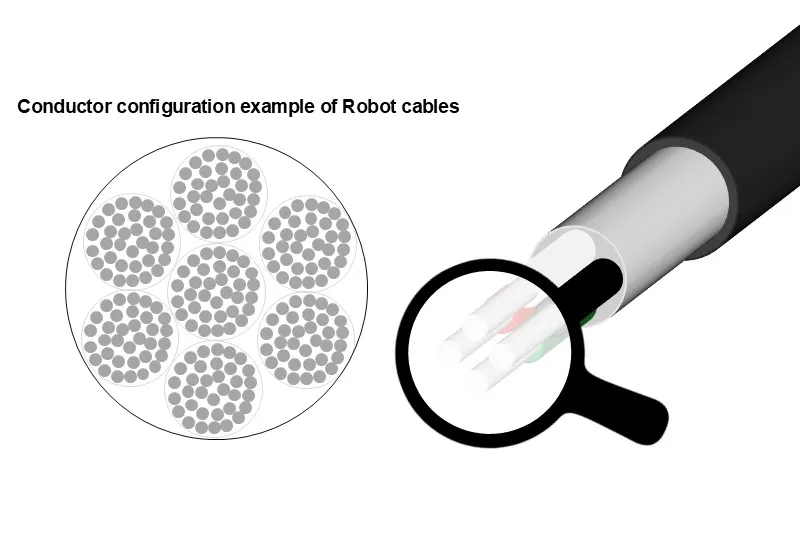

Conductor is responsible for transmitting electricity such as power and signals.

When it comes to the conductor material, We use copper for three reasons: low resistance, cost, and light weight.

In addition, the conductor wires are made of ultra-fine wires the size of a hair, and several of these ultra-fine wires are twisted together and then the bundles are twisted together.

This configuration improves flexibility compared to the conductors used in standard cables. *In the case of standard cables, the conductor wires are twisted together as they are.

Insulation

Insulation serves the purpose of blocking the conduction of electricity. We use insulating materials that are "hard and slippery" to prevent wire breakage.

If the insulation is soft, it may bend locally, leading to premature breakage.

Furthermore, if the insulation does not slide smoothly, the assembly of the insulated wire core may become disrupted, which may lead to breakage.

In addition, we use "special elastomers" and "ETFE" as insulating materials that are hard and slippery.

- Robotic cable series with special elastomer insulation・・・RMDH, RMDV

- Robotic cable series with ETFE insulation・・・RMFEV

Shield

Shield serves the purpose of preventing noise.

We have adopted braided shield after taking into consideration factors such as bending resistance and shielding effect.

Furthermore, Robotic cable with braided shield has "-SB" in the model number.

e.g. RMDH-SB、RMFEV-SB

Jacket

Jacket serves the purpose of preventing external damage and providing oil resistance.

For this reason,taking into consideration the flame retardancy and oil resistance of the sheath, we use flame-retardant・oil-resistant PVC.

Moreover,we also offer special conductor, special shield, and special jacket depending on the usage environment. Details are available here.

About DYDEN's Robotic cables

Three features

There are several manufacturers of Robotic cables, including us, but among them, "What are the features of DYDEN's Robotic cables...?" Our Robotic cables have three main features.

①More than 40 years of experience and data (reliability)

②Custom design suggestions

③In-house material development

More than 40 years of experience and data (reliability)

We have been dealing in Robotic cables for over 40 years, since we began manufacturing them in 1983.

We have over 80 testing machines capable of ±90° bending, torsion, and cable gude motion, and the know-how and technical capabilities we have accumulated by repeatedly conducting rigorous tests have ensured the long life and durability of our Robotic cables.

▼For more information about the test machine, you can check here.

Custom design suggestions!

We also carry out custom designs according to customer requests based on the product lineup listed on our website.

The RMDH Series, RMDV Series, RMFEV Series, and RMCV Series are available as custom series.

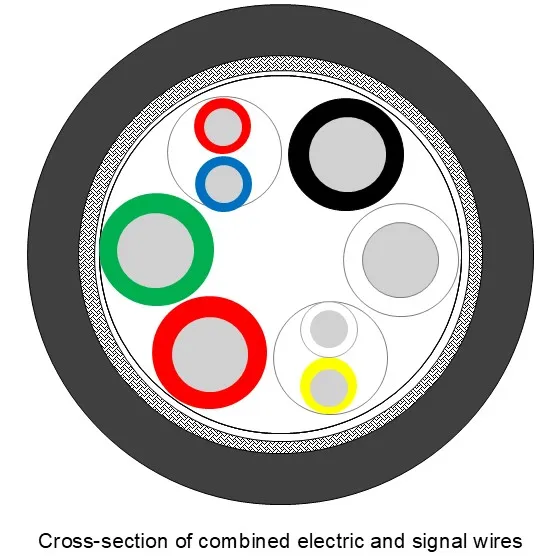

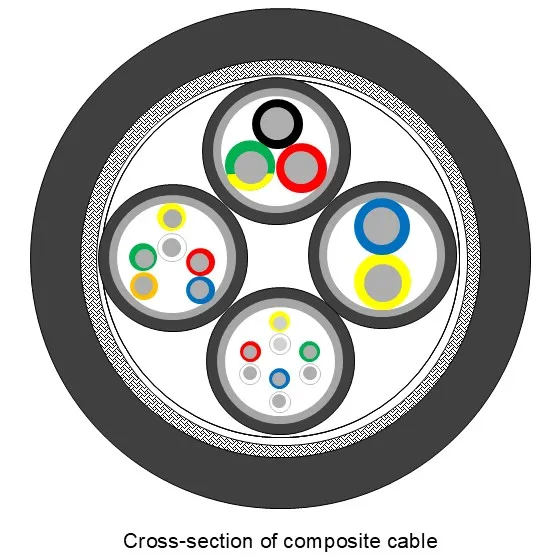

For example, we can accommodate a variety of requests, such as combining power lines and signal lines, as shown in the image, or consolidating multiple cables into one.

In particular, consolidating multiple cables into one is ideal for use in tight wiring spaces such as inside robots, and has been well received by many customers.

▼For more information on custom designs, please see this page.

In-house material development!

We develop cable materials in-house that are optimal for each customer's intended use.

For example, the "RMDH Series" uses a special elastomer, an insulating material developed in-house.

The RMDH series is a cable created in response to customer requests such as "I want to make my robots smaller" and "I want to save wiring space." In order to reduce the outer diameter of the cable, the insulation thickness can be thinned, and a thinner cable diameter means a smaller robot and more space-saving wiring.

In this way, we also develop materials in-house to meet the needs of our customers.

▼For details on the RMDH series, please click here.

Market share in Japan

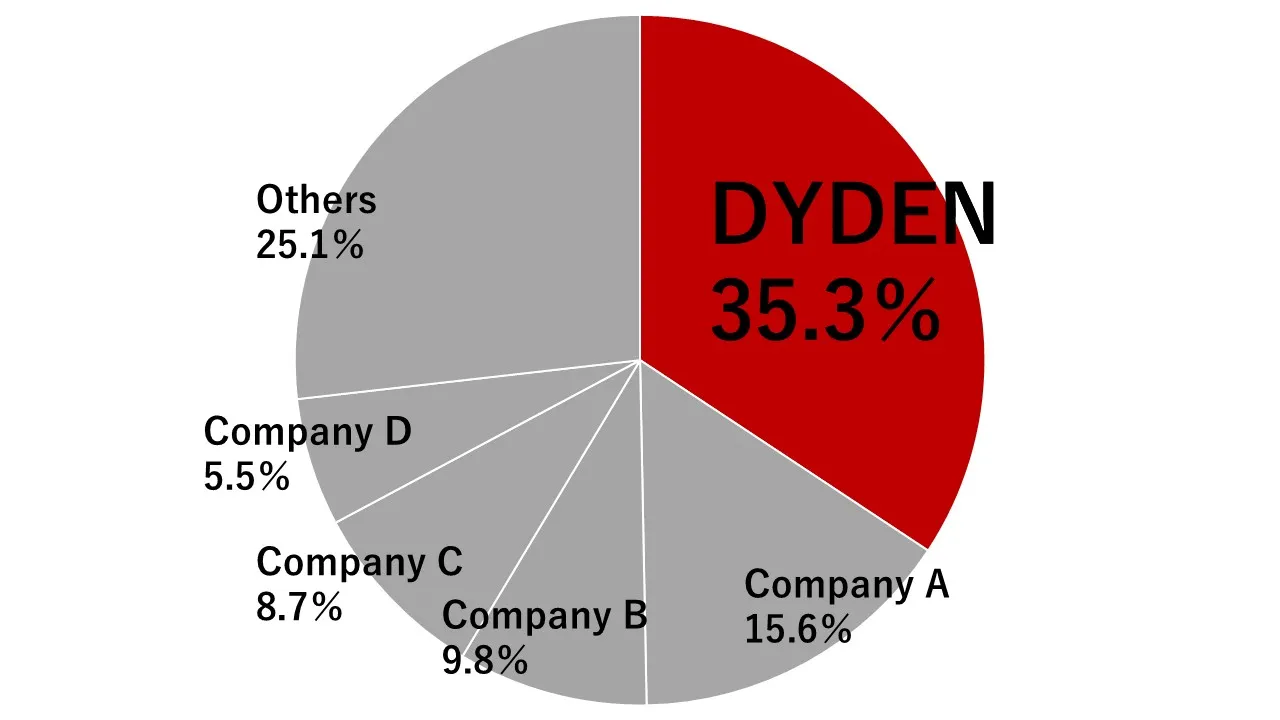

With these three features, our Robotic cables have been highly praised by major robot manufacturers and others.

▶Click here for a list of our employment results.

Despite being in a highly competitive industry, we have maintained the number one market share in Japan for many years.

Japanese market share of FA cable sales (2024)

(*Refer to Fuji Keizai’s No. 1 The Robot-related Market Worldwide: Current Status and Prospects for the Future, Robots for FA)

Summary

This article introduced the overview of Robotic cable (how they differ from general standard cable), their structure, three features, and their market share in Japan. Finally, we have summarized the contents of this article below:

▼Summary of this article

- Robotic cables are used for industrial robots, etc., and unlike standard cables, they are flexible and twistable.

- The structure is made up of a Conductor, Insulation, Shield, and Jacket.

- Our Robotic cables have the following features: "More than 40 years of experience and data (reliability)" "Custom design suggestions!" and "In-house material development!" and they have the largest market share in Japan.

We have a lineup of various series of the cables introduced this time.

Also, We have a page where you can select the most suitable series for you from the many series available. You can select the most suitable cable series by checking the purpose and conditions of use. Please make use of it!

If you have any requests, such as "I would like you to suggest the best cable" or "Please tell me your distributor," please feel free to contact us.